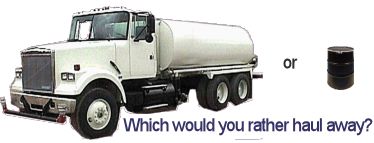

From Tankers to Drums: Reducing Haul Away

CASE STUDY FOR POLY PRODUCTS INC.

By Jeff Kubiak, Vice President of Sales

jkubiak@metchem.com

The Client:

A well known leader and developer in the semiconductor industry and newly established provider of advanced LED lighting and display technology, has recently relocated to a new state-of-the-art manufacturing facility in the greater Cleveland, Ohio area.

The Problem:

While residing at its previous facility, this company endured substantial costs in having to haul away the waste water from the nickel sulfamate rinse in their electro forming process. They realized that their new facility would need to be environmentally friendly and cost efficient, so they called Poly Products.

The Process:

Poly Products reviewed their needs and offered choices based on their goal to reduce costs in an environmentally conscious way. By choosing to use the Poly Products Turn-key Evaporation system to heat the waste water in an off-line electrically heated system, the waste water volume will be reduced as it is fed from their bulk storage collection pit.

The Solution:

As a result of using the Poly Products Evaporation System, the waste water volume is reduced by evaporating the water out of the waste stream as the impurities collect as solids. These solids are then hauled away in a fraction of the volume and at a fraction of the cost of the original system. What was originally tanker truck volumes are now only 55 gallon drum volumes. This company now achieves their goal to reduce haul-off costs by a substantial margin, therefore offering them freedom in ways that go beyond financial rewards. Rinse water is used liberally to  ensure complete and thorough rinsing and production quality. They now have the freedom to increase their R&D efforts without the burden of increased waste water expense as the Poly Products Heated Tank Evaporation System accommodates all waste volumes comfortably.

ensure complete and thorough rinsing and production quality. They now have the freedom to increase their R&D efforts without the burden of increased waste water expense as the Poly Products Heated Tank Evaporation System accommodates all waste volumes comfortably.