Heated Tank System

|

Heated Tank Evaporator System ™ shown with the ET-Companion ™ Condenser |

The Poly Products Evaporator System evaporates water from process solutions and waste waters under atmospheric conditions. The highest evaporation rate can be achieved by heating the solution prior to pumping it into the evaporator.

This is accomplished by using our heated tank with either a gas-fired burner, steam coil or electric heater. The patented (#4790904) ET Evaporative Tank ™ is molded out of polyethylene, with no weld seams, for leak-free operation. With over 2,000 products in the field, the Poly Products evaporator has proven to be the leader in atmospheric evaporation of water.

Systems Includes:

- Evaporative Tank ™

- Stainless steel heated tank and fire tube (carbon steel and polyethylene are also available)

- Gas fired burner, steam coil, or electric heater

- Control panel with temperature control, over temperature protection and level controls for automatic operation

- CPVC or stainless steel centrifugal pump to feed evaporator

- Skid mounting with piping and wiring installed at the factory

Heated Tank Evaporator |

Dimensions |

Evaporation * |

Heater BTU |

ET Companion |

|---|---|---|---|---|

| ET-III-W-1-MINI.-55-40** | 4'x 8'x 9' | 40 GPH | 550,000 | No |

| ET-III-W-1-MINI.-55-40-C** | 4'6" x 9'6" x 9' 6" | 40 GPH | 550,000 | Yes |

| ET-III-W-1-HT-55-40 | 7' x 9' x 13'9" | 40 GPH | 550,000 | No |

| ET-III-W-1-HT-55-40-C | 7' x 9' x 13'9" | 40 GPH | 550,000 | Yes |

| ET-III-W-2-HT-1.0-80 | 7' x 1 0' x 13' 9" | 80 GPH | 1,000,000 | No |

| ET-III-W-2-HT-1.0-80-C | 7' x 1 0' x 13' 9" | 80 GPH | 1,000,000 | Yes |

| ET-III-W-3-HT-2.0-120 | 8' x 15' x 13' 9" | 120 GPH | 2,000,000 | No |

| ET-III-W-3-HT-2.0-120-C | 8' x 15' x 13'9" | 120 GPH | 2,000,000 | Yes |

| ET-III-W-4-HT-2.5-160 | 8' x 20' x 13' 9" | 160 GPH | 2,500,000 | No |

| ET-III-W-4-HT-2.5-160-C | 8' x 20' x 13' 9" | 160 GPH | 2,500,000 | Yes |

* The above evaporation rates are based on water. Evaporation rates will vary as the solution thickens and has less water content. |

||||

ET-Companion ™ Condenser for recovery of the evaporated water for reuse

ET-Companion ™ Condenser for recovery of the evaporated water for reuse - Insulating the heated tank

- Filter press for continual solids removal

- Storage tanks

- Pump stations

- Cooling tower for ET-Companion ™ Condenser cooling water

- Above dimensions can be altered to fit special installation requirements

- Titanium electric heaters or De-Rated Teflon coated electric heaters for extremely aggressive solutions

|

|

||

MINI series is a more compact version and does not include platform and stand. |

ET-Companion ™ Condenser for closed loop recovery of water and plant air |

||

|

|

|

|

Control panel for heated tank system |

Heated tank with gas fire tube |

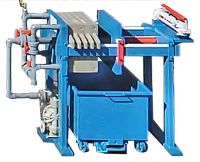

Filter press with polypro plates for solids removal ranging from .5-100 cubic feet capacity |

Filter Press |